New Portable Hardness Tester is different from Ultrasonic thickness

Tester with multi-point calibration to precision

Introduction

This hardness tester is designed for testing metallic materials,

the hardness of which ranges from very low to very high values.

Hardness testing can be performed directly on-site and in any

position. Typical applications are large, heavy workpieces which

could only be transported to a hardness testing machine in a

laboratory with great difficulty. It is especially suitable for

applications in which standard indentation hardness testing is

either not feasible or not economical.

This hardness tester comprises an indicating device and an impact

device. It is based on the rebound hardness testing method

according to Leeb. It is for testing the hardness of all material

surfaces over a large range of hardness quickly and independently.

Advantages

Wide measuring range

Based on the principle of Leeb rebound testing method, it can

measure the hardness value of all metallic materials. It can also

measure the tensile strength of many metallic materials.

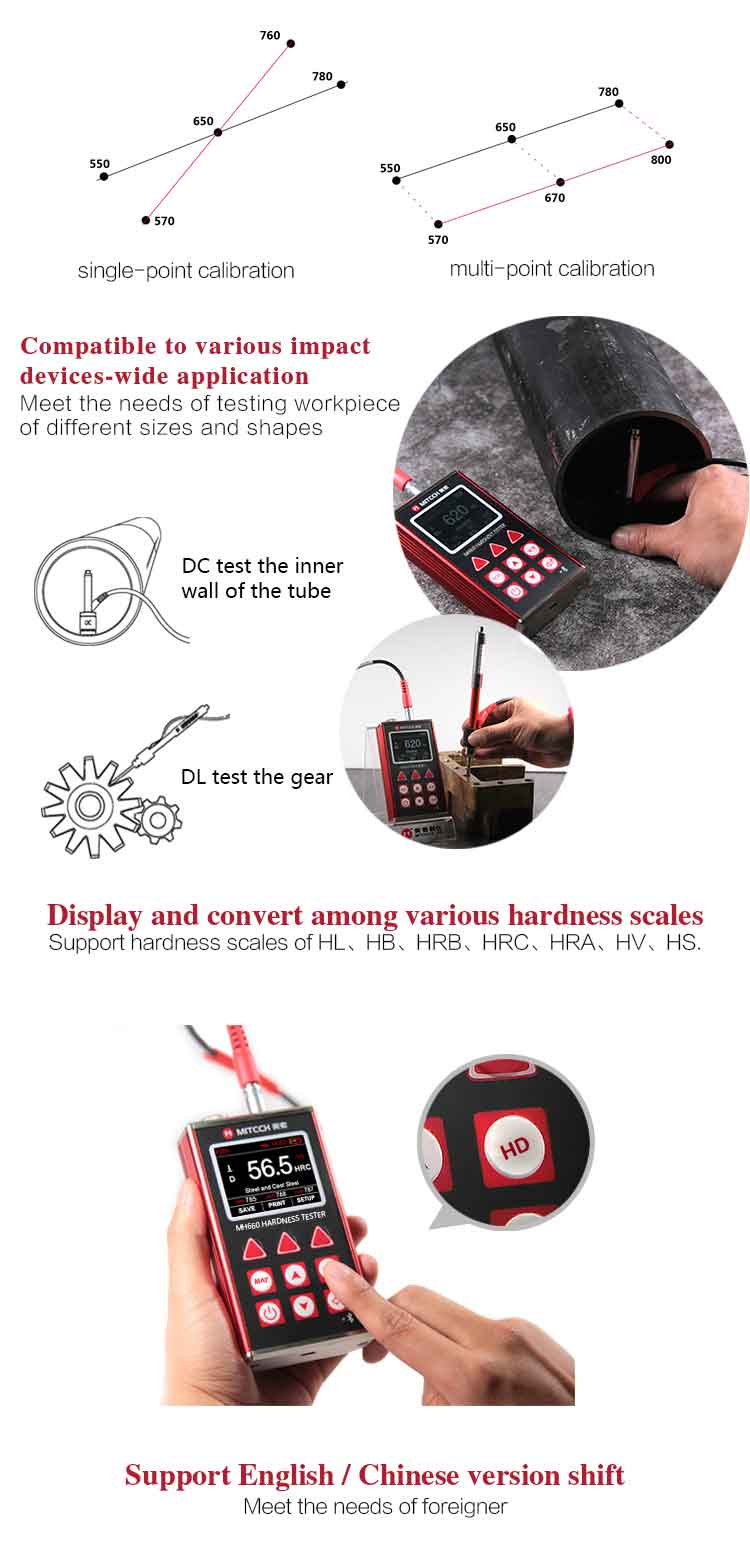

Impact device

Support seven types of impact device. Type of impact device

automatically identified.

Impact direction correction

Impact direction automatically detected and corrected (after base

calibration, except type G) , high measuring accuracy in every

impact direction, convenient measurement in any position.

Scale

Integrated conversion of the measured values to other popular

hardness scales, e.g. HRC (Rockwell), HRB, HV (Vickers), HB

(Brinell), HS (Shore), HL (Leeb), Rm (Tensile strength for steel).

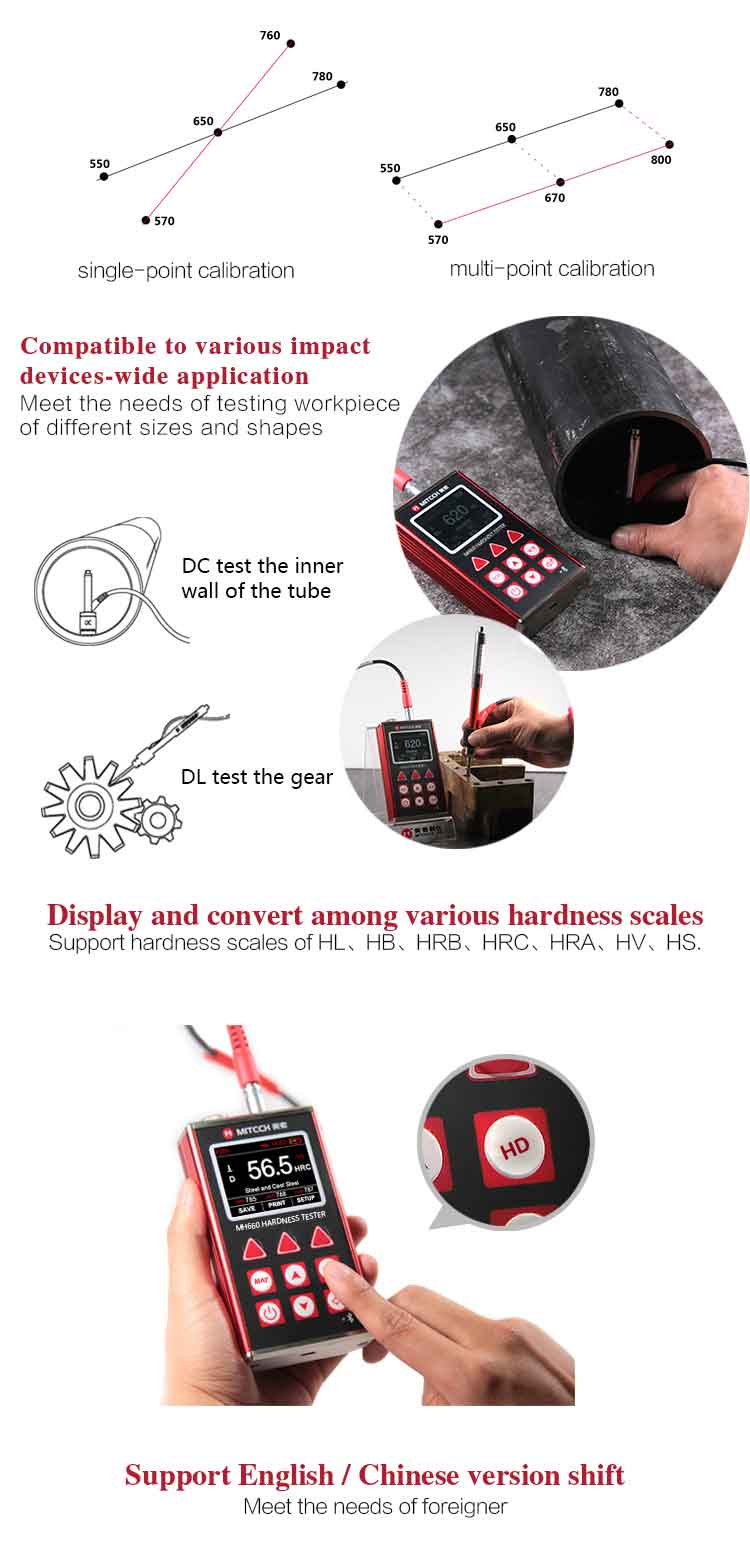

Calibration

Base calibration function and multi-point calibration function.

HLX conversion function

HLX conversion function to convert HLD values to HLC, HLG, HLDL and

HLD+15, and vice versa.

Tolerance limit

Upper and lower limit can be set. It will alarm automatically when

the test value exceeding the limit.

Display

Color TFT display (320×240 TFT LCD) with adjustable backlight,

allow the user to work at worksites with low visibility.

Memory

Integrated memory – Non-volatile, 500 series of measured values

including each individual measured value, mean value, testing date,

impact direction, impact times, material and hardness scale etc..

Power saving

Two AA size alkaline batteries as the power source. Continuous

operating period of no less than 100 hours (default brightness

setting). Display Standby and Auto Power Off functions to save

power.

Real time clock

The instrument clock keeps running tracking the time.

Communication

USB communication port. Online transfer of the measured data to PC

or laptop via USB.

Printing

Built in Bluetooth module. Print test report wirelessly.

Robust design

Robust design allow the user to work at dusty worksites .

Technical specifications

The error and repeatability of the test value see the following

table.

| No. | Impact Device | Hardness value of the test block | Measuring accuracy | Measuring Repeatability |

| 1 | D | 760±30HLD 530±40HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

| 2 | DC | 760±30HLDC 530±40HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

| 3 | DL | 878±30HLDL 736±40HLDL | ±12 HLDL | 12 HLDL |

| 4 | D+15 | 766±30HLD+15 544±40HLD+15 | ±12 HLD+15 | 12 HLD+15 |

| 5 | G | 590±40HLG 500±40HLG | ±12 HLG | 12 HLG |

| 6 | E | 725±30HLE 508±40HLE | ±12 HLE | 12 HLE |

| 7 | C | 822±30HLC 590±40HLC | ±12 HLC | 12 HLC |

- Measuring range:170 to 960 HLD

- Impact direction:360°. Auto detecting direction capability.

- Built in conversion table from(to) HLD to(from) HLC,HLG,HLDL,HLD+15

- Hardness Scale:HL,HB,HRB,HRC,HV,HS

- Display:color TFT LCD,320×240 dots, adjustable backlight

- Display of mean value, minimum value and maximum value.

- Integrated data memory: 500 measurement series.

- Battery: two AA size, 1.5 Volt alkaline batteries

- Continuous operating period:about 100 hours(with default

brightness)

- Communication:USB1.1; PC software is provided to transfer data

between the instrument and PC.

- Bluetooth support.

- Multiple display languages (English, Chinese, etc.).

- Weight: Approximately 220g.

Dimensions:120mm×67mm×31mm.